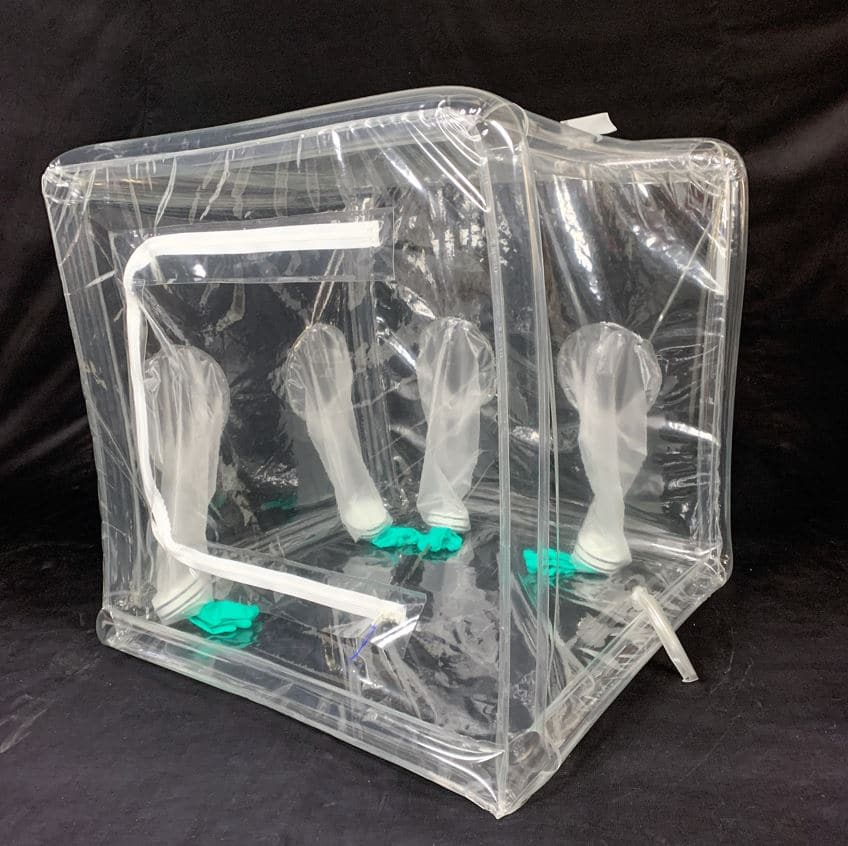

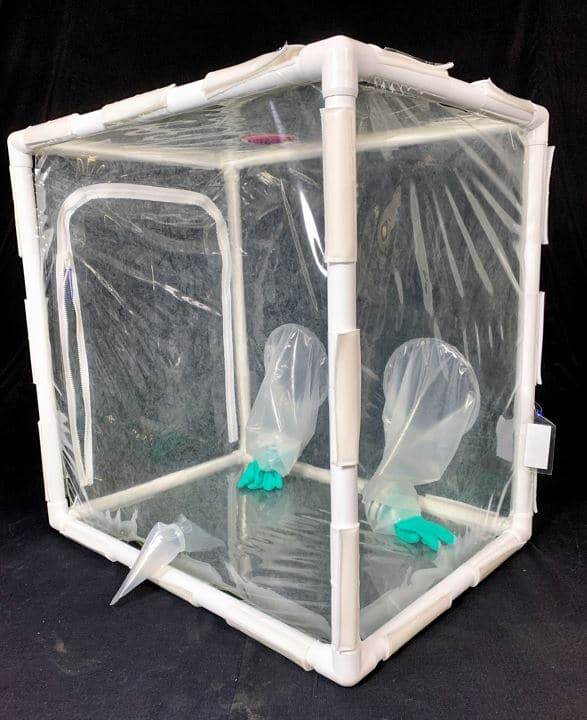

FabOhio, Inc. is positioned to offer low cost, high quality, see-through hermetic enclosures that are environmentally acceptable for disposal at a fraction of the cost compared to a non-disposable system.

By selecting polyurethane film Containment Isolators for the Pharmaceutical Industry, FabOhio, Inc. established many design precedents. The films compatibility with EMA and FDA performance criteria along with film flexibility below freezing and up to 160oF, high tensile strength, opacity, impermeability, chemical resistance, and absence of chemical emissions have allowed us to solve many challenges for our clients. These characteristics continually allow us to expand our capabilities far beyond those of other film matrices.

Working with a client requiring controlled environmental conditions, we solved the challenge using a purging technique developed for our Nanoparticle-free isolator. This in turn was an extension of the principles used for exponential room cleaning (fog/mist method) since 1993. Polyurethane film flexibility was the key to repeat purge cycles of inflation and deflation with the environmentally selected airflow. Currently HEPA, moisture, and nanoparticle filters are available, while users can create their own airflow matrix from readily available supplies.

Contact us at FabOhio, Inc. with any questions, we would be more than happy to discuss containment details for your business’ custom hermetic isolator system.

Written by Brian Ward, PhD, CSci, CChem, FRSC