Why We’re Different

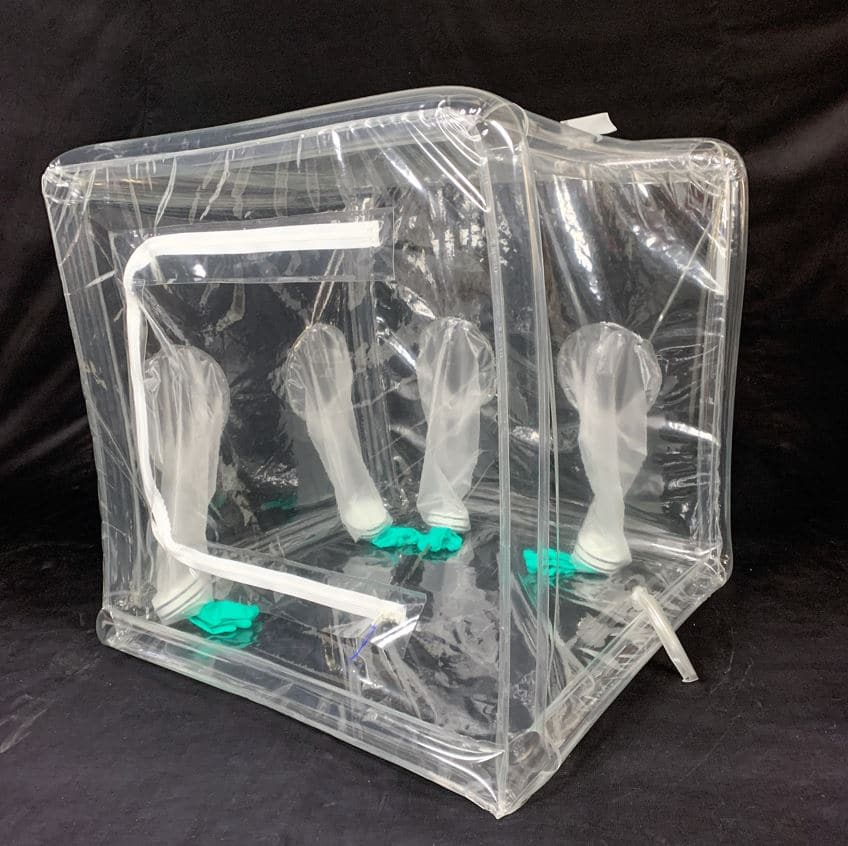

As the originators of the glovebag, we offer flexible containment that demonstrates outstanding levels of efficiency and performance.

Superior Containment Performance

When our flexible barriers are installed correctly, they perform as effectively as a rigid containment and far better than an airflow barrier system.

Until ca. 2000 the best analytical sensitivity for testing rigid and flexible isolators using surrogate challenges was 0.2 ng/m3. Testing of our flexible isolators showed measurements below the analytical detection limit, which approximates to a Containment Factor of >3,000.

With improvements in analytical sensitivity, isolator performance has become quantifiable at the analytical detection limit of 0.2 ng/m3 for a full period measurement of a procedure, corresponding with a Containment Factor of >1014. When properly installed and used, our flexible isolators typically achieve non-detectable emission levels.

Effective Radiation Conditioning

Studies conducted by an independent laboratory confirm the efficacy of the radiation dosages we have established. The biological efficiency exceeds a kill factor of 106 for a standard battery of organisms.

Selection of e-Beam radiation precludes the formation of pinholes in the film structure. The integrity of our flexible barriers was maintained through levels up to 10 times the established conditioning dosage.

Clients who select premium e-beam decontamination as an add-on service are provided with a confirming Certificate of Irradiation with their shipment. Dosage tags remain on the conditioned shipping container.

Flexible Barrier Installation and Training

FabOhio Inc. stands ready to assist clients requesting the installation of flexible barriers and operator training. A cost proposal will be provided for this service.

We strongly encourage clients to establish a lead person responsible for working with FabOhio Inc. who can learn to install flexible barriers and conduct training sessions for their end-users.

Versatile Solutions to Meet Any Challenge

The versatility of flexible containment applications that we support covers the entire life cycle of Pharmaceutical products, from discovery through to product packaging.

High-Quality Materials of Construction

Our materials of construction meet all current regulatory requirements, and we take extra steps to ensure the durability and reliability of our containment solutions.

For example, it’s imperative that you use the correct type of film for containment products to avoid fragility. Our film is shock cooled to prevent it from crystallizing.

Material Data Sheets (MDS) are available on our website for quick reference.